6 Common Issues with Resurfacing Your Deck

February 14th, 2024

5 min read

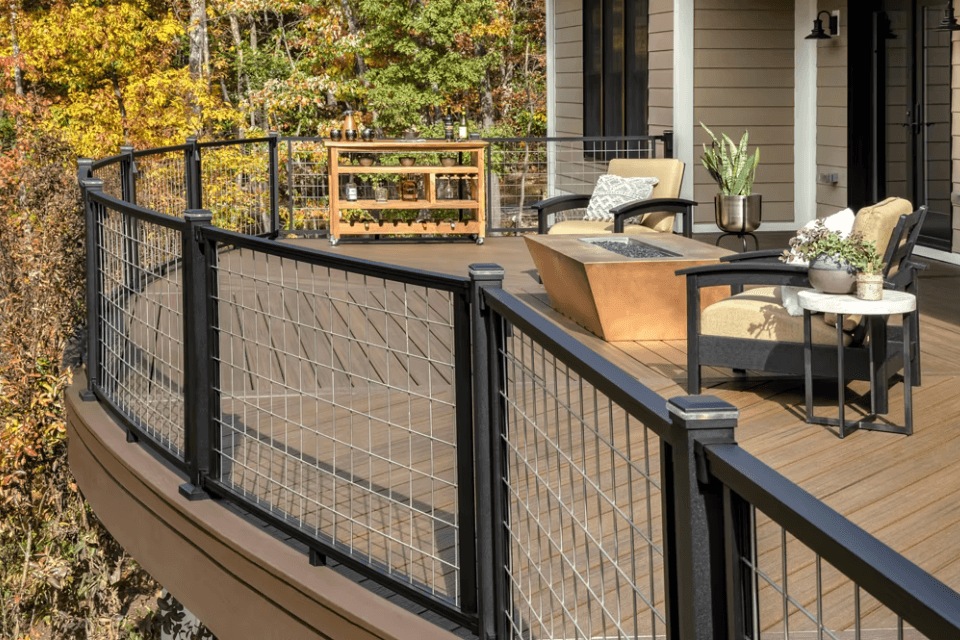

Are you considering resurfacing your deck? While choosing to keep your deck structure can be a great solution to save time and money, there are several common problems you should be aware of before committing to this solution.

Over the past 15+ years, our team has worked with numerous homeowners to assist them in deciding whether resurfacing or replacing their deck structure is the best solution. Our goal is to help you create the outdoor space of your dreams by providing a solution that withstands the test of time.

In this comprehensive article, we'll unravel the common issues with replacing deck boards and how to combat them:

- Existing Structure Strength

- Common Weak Points

- Navigating Material Selections

- Pursuing Permitting and Regulation Approvals

- Addressing Structural Repairs

- Preparing for the Unknown

1. Existing Structure Strength

Before delving into the process, it's crucial to assess the existing deck structure thoroughly. You should keenly observe for common issues that might compromise the structural integrity, such as rot, decay, or weakened supports.

Identifying these concerns early on is pivotal in preventing further damage and ensuring a safe and durable deck.

Additionally, it’s essential to know the load-bearing capacity of your deck, differentiating between materials like composite and wood and their unique weight requirements. This awareness not only aids in selecting suitable resurfacing materials but also ensures that the revamped deck can comfortably accommodate the envisioned outdoor activities.

Here are a few ways you can find out about the load-bearing capacity of your deck:

- Identify Support Structures: Examine the deck's support structures, including posts, beams, and joists. Understanding the materials and dimensions of these components is essential for determining load capacity.

- Consult a Professional Inspector: Hire a structural engineer or a qualified deck inspector to assess the load-bearing capacity. They can thoroughly inspect and provide detailed insights into the deck's structural integrity.

- Consider Local Building Codes: Familiarize yourself with local building codes and regulations. These codes often specify load-bearing requirements for different types of structures, including decks. Ensure that the deck complies with these codes.

2. Common Weak Points

Common Weak PointsExample of uneven deck boards

Simply put, you can’t resurface your deck without addressing weak points in your existing structure. Let’s dive deeper into the weak points you should look for before starting your deck resurfacing:

- Cracked or Split Beams: Examine horizontal beams for cracks or splits. Damaged beams can compromise the load-bearing capacity of the deck.

- Warping or Twisting Boards: Warped or twisted deck boards are not only unsightly but also potentially unsafe. Replace any boards that show severe warping.

- Unstable Support Posts: Assess the condition of support posts, ensuring they are securely anchored and not showing signs of tilting, shifting, or visible damage. Like rotting at grade.

- Sagging or Uneven Joists: Sagging or uneven joists may indicate structural weaknesses. Use a level to check for any noticeable deviations from a flat and even surface.

- Loose or Corroded Fasteners: Inspect the deck for loose or corroded screws, nails, or other fasteners. Weak connections can compromise the overall stability of the structure.

- Rot and Decay: Check for signs of rot or decay in wooden components, especially in moist areas. Soft, discolored, or easily splintered wood indicates potential issues.

- Inadequate Ledger Attachment: Ensure that the deck ledger, the part attached to the house, is securely and adequately fastened. Improper ledger attachment is a common weak point.

- Insufficient Support for Additional Weight: Assess the deck's capacity to support additional weight, especially when switching to heavier materials like composite decking. Ensure the structure can handle the increased load without compromising safety.

3. Navigating Material Selections

Choosing the suitable material for your deck is a critical decision beyond aesthetics. The array of options, including treated lumber, composite, or cedar, can be overwhelming.

Pro Tip: If you are not improving the structure, match your resurfacing material with what was previously on your deck. A wood deck frame may not be built to withstand the weight of heavier composite boards. Installing mismatched materials without strengthening your structure will result in structural issues over time.

When deciding on your material, check the guidelines, approved fasteners, and warranty details from the manufacturer. Look into the specifics to understand the structural differences and unique features of each material. This will create a deck that looks gorgeous, follows the installation guidelines, and lasts.

Here are the various wood and composite options you can pursue as you resurface your deck:

Resurfacing with Wood:

- Pressure-Treated Wood: A cost-effective option resistant to decay and insects. Regular maintenance, such as staining or sealing, enhances durability.

- Tropical Hardwoods: Exotic hardwoods like Ipe or Mahogany provide exceptional durability and a rich appearance. They often require specialized tools for installation.

- Cedar or Redwood: Offers natural beauty and resistance to decay. While higher in cost, these woods require less maintenance and age gracefully with a distinctive patina.

Resurfacing with Composite:

- PVC Decking: Made from polyvinyl chloride, PVC decking is durable, low-maintenance, and resistant to moisture, insects, and rot.

- Composite Railing Systems: Complete the look with composite railings that offer a cohesive appearance and low maintenance compared to traditional wood railings.

- Capped Composite Decking: Combines a wood and plastic composite with a protective cap for enhanced durability and resistance to fading, staining, and mold.

4. Addressing Structural Concerns

When it comes to resurfacing projects, addressing structural repairs is often necessary. Hiring a knowledgeable contractor who understands load-bearing capacity, deck foundations, and the structure's lifespan can simplify this process. Their expertise makes structural repairs straightforward, ensuring a durable and safe outcome for your outdoor space.

5. Pursuing Permitting and Regulation Approvals

When resurfacing your deck, no permits are needed in the Lansing area (Disclaimer: Permits are still required if you are replacing stair rails and steps). You can enjoy the process without dealing with complicated paperwork. However, keep in mind that if you uncover structural problems during resurfacing and need to reinforce your structure or completely replace your deck, permits are required.

A reliable contractor or design-build firm can simplify the process and guide you through any necessary permitting for a safe and compliant outcome.

6. Preparing for the Unknown

When revamping your deck, it's crucial to prepare for the unknown. Depending on your deck layout, issues like hidden mold, rotting boards, or foundation problems may only become visible after removing the deck boards.

Dealing with these hidden challenges requires careful disassembly, leading to extra labor and potential additional costs. Understanding these potential issues will help you approach your project with awareness, ensuring a thorough and successful transformation of their outdoor space.

Hiring the right deck contractor is crucial when unexpected issues arise during a resurfacing project. An experienced contractor can tackle unforeseen challenges, ensuring the project stays on course and meets safety standards.

Whether dealing with structural concerns or adjusting to changes, a reliable contractor brings the expertise needed to overcome obstacles. Choosing the right professional not only ensures a successful deck resurfacing but also provides peace of mind, knowing the project is in capable hands and ready to handle any surprises.

Next Steps to Resurfacing Your Deck

Resurfacing your deck is an exciting adventure leading to rejuvenated, usable outdoor living space.

In this article, we've provided insights and expertise to empower you in making informed decisions.

With our 15+ years of deck-building experience, we've walked alongside hundreds of homeowners and their deck builds. We understand the importance of a well-crafted outdoor space.

As you proceed with your deck replacement project, we encourage you to connect with us. We can offer personalized guidance, address specific observations, and build your timeless retreat. Contact us today to transform your deck into a space that blends beauty and durability.

Now that you know more about the common issues with replacing deck boards, explore how Custom Built will approach your project, how much your new outdoor living space will cost, and how long it’ll take to build:

- Dream, Design, and Build: Our Remodeling Process - This guide details how we at Custom Built will approach your remodeling project.

- How Much Do Composite Decks Cost in Lansing, Michigan? - An overview of how much your Lansing composite deck will cost and the factors that will influence your price.

- How Long Does it Take to Build a Deck (Factors that Affect Timeline) - Explore details that affect how long it takes to build your composite deck with Custom Built’s Proven Process as the foundation.

Michael brings over 2 decades of building and remodeling experience to his position as the Owner and Visionary of Custom Built. Michael’s passion to make an impact on the home building industry has led him to serve for over ten years at the local and state Home Builders Association, culminating as President of the HBA of Michigan in 2020.