Ready to build your dream deck but need help determining which material to install? Due to its recent spike in popularity, composite decking might make you feel stuck in one option for your deck remodel.

Even worse, committing to this option without a full picture of the negatives could result in a finished project that you aren’t satisfied with.

We understand that you deserve full transparency when researching materials for your to-be dream deck. Our mission at Custom Built is to not only design and build the dream decks of Mid-Michigan homeowners but also to educate you on everything related to home remodeling.

In this article, you will learn what composite decking is, the problems you might encounter, and how they can affect your deck build or remodel:

What is Composite Decking?

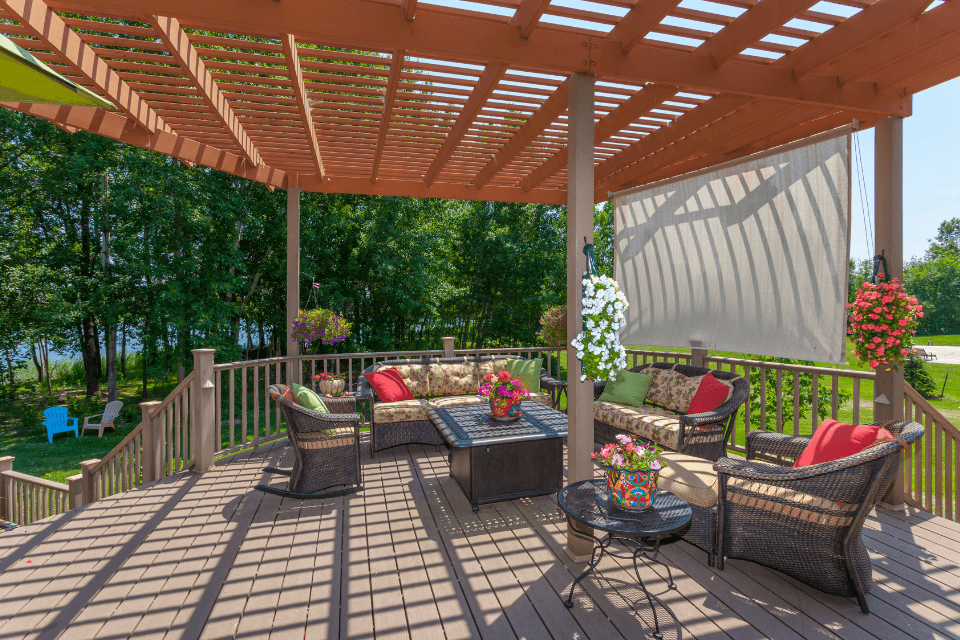

Composite decking is an alternative to traditional wood decking usually made of wood fiber, resins, recycled plastics, and polymer materials. Longer-lasting and more eco-friendly, composite decking has stolen the show and won the hearts of homeowners over the years.Here are a few more pros you can expect from composite decking:

- Less overall maintenance

- Many color/design options

- Realistic wood appearances (without the splinters)

- Less expensive than wood decking in the long run

While composite decking is an amazing option you can leverage for your outdoor entertainment area, it’s essential to recognize the potential downsides you may encounter.

1. Composite Decking is Known for Scratching

PC: Decks.com

Unfortunately, composite decking isn’t indestructible. Dragging heavy furniture or dropping sharp objects can and will scratch your deck.

A brush of paint or two should fix it, right? Not quite.

Since PVC surrounds the wooden core of composite deck panels, typical oil-based paint has a harder time adhering to the surface and is prone to peeling. To prevent this, we recommend placing furniture pads or rugs underneath the legs of your furniture or strengthening your deck with composite sealant.

2. No Room for Production Errors in Composite Decking

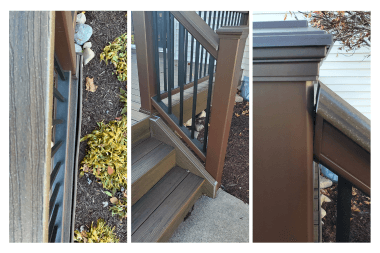

Examples of poorly installed deck boards and railings (Left to Right: Uneven installation, Deck board awkwardly cut below railing, Gap between railing and post)

With any deck build - scratch that - any build in general, the success of your project depends on the capability of the workers’ efforts.

While composite decking is more affordable and durable than wood decking over time, but replacing poorly installed panels is not cheap. One miss-cut or poorly cut board, and, you could be out an extra $50-$100 per 1 in. x 6 in. x 8 ft. deck board - which can add up quickly.

On top of higher production risks, a botched installation could lead to more structural issues. You might encounter the following problems if your composite decking is improperly installed:

Joist Deflection

Incorrectly spaced joists (horizontal structural components that provide support for a deck's surface boards) or warped joists could result in uneven boards, making the deck appear wavy and potentially creating a walking hazard to trip over. As opposed to regular wood decks that are more forgiving, joists for composite decking must be precisely placed to accommodate and support the board’s plastic material.

Improper Fastener Application

Fasteners, once screwed in, are used to hold deck boards in place. Every composite decking manufacturer requires their own fasteners and clips - each featuring an installation guide that dictates which fasteners its warranty will honor and how to install them. Typically, contractors who incorrectly install them result in spacing and security issues down the line.

Local Codes or Minimum Standards Not Followed

All decks should be held to the manufacturer’s specifications, meaning your composite decking must match a quality standard before being installed. If your contractor ignores this and underestimates your deck’s load capacity (average weight distribution on top of the deck is around 300-800 pounds per square foot), you might find yourself and your new grill spontaneously “below deck.”

If your deck framing plan follows local codes and the manufacturer's installation guidelines, then there should never be an issue with load capacity - with the exception of placing fixtures like hot tubs or swim spas. Simply put, there is no room for improper or poorly engineered sub-structures when it comes to composite decking.

This is why it’s important to find a contractor you can trust to hold themselves accountable to the manufacturer’s expectations, protecting the integrity of your build and ensuring you receive the maximum product warranty for your correctly installed materials.

3. Risk of Mold and Mildew in Composite Decking

Before and After Mold Cleaning/ PC: 30 SECONDS CLEANERS

Yes, you read that right: lower-quality composite decking is more susceptible to mold and mildew than higher-quality composite decking.

As we reviewed earlier, composite decking is made up of a blend of wood flour and plastics. Because it still has wood components, its panels can become a hot spot for mold and mildew.

In Michigan’s rainy and humid climate, water can seep into tiny crevices, sticking to those granular wood particles, and eventually sprouting bacteria. Additionally, unwashed decks harbor the same bacteria that could lead to mold.

However, this can easily be avoided by choosing a high-quality composite material, regularly cleaning and inspecting your deck for mold, eliminating extra shade to encourage air ventilation and drying, and promptly draining or removing standing water.

For a more in-depth look into how to care for your composite decking, check out this valuable guide from our friends and suppliers at Trex.

Next steps to choosing which decking option is right for you

With so many composite decking options in the marketplace, it is even more critical to connect with an expert to help ensure that what you choose will serve your needs for the foreseeable future.

Our recommendation moving forward? Reach out to an expert, look up examples of successful and unsuccessful composite deck builds,, and give yourself enough time to vet the choices that’ll match your vision.

You have learned the real problems with composite decking, an important step before signing a contract on one particular type of decking.

We’ve seen it all when it comes to deck rebuilds. At Custom Built, we understand that sometimes the popular choice isn’t always the best choice no matter what kind of project you want to pursue - especially when the end product is something you have to live with and see every day.

Now that you've learned more about the issues you might encounter with Trex composite decking, let's take a look at its benefits and differences compared to wood decking:

-

Top 4 Composite Decking Brands 2023 - A brief overview of the top brands you should consider using when installing your composite deck.

-

Top 10 Differences Between Trex Composite and Wood Decking Material - A list of the top differences between the industry's top two decking options.

-

Is Trex® Composite Decking the Right Material for Your Deck? - This article explores the top qualities of composite decking compared to other top decking choices.

Michael brings over 2 decades of building and remodeling experience to his position as the Owner and Visionary of Custom Built. Michael’s passion to make an impact on the home building industry has led him to serve for over ten years at the local and state Home Builders Association, culminating as President of the HBA of Michigan in 2020.